Service hotline

86-18561281819Application Cases

Quick navigation

Inkjet materials

What is digital inkjet ink? What are its main components?

Digital ink is a special colored colloid used to record patterns on substrates such as paper or lightbox cloth. The three main components of ink include colorants (pigments), crosslinkers (resins), and solvents. The ink mixture including the solvent is sprayed onto the substrate, and as the solvent evaporates and dries, the cross-linking material firmly combines the colorant (pigment) with the substrate to form a pattern.

Divide digital ink types by ink attributes:

Divided by ink base:

1 water-based type

According to its characteristics, it is mainly divided into solution ink, diffusion ink, and microemulsion ink;

2 Non aqueous type

According to its characteristics, it is mainly divided into oil-based ink and solvent ink (weak solvent ink);

3 Phase change type

According to its characteristics, it is mainly divided into two types: liquid to colloidal and liquid to solid;

4 reactive type

According to its characteristics, it is mainly UV cured and does not contain volatile solvents. After curing, it has good light resistance and water resistance, and can generally be printed on items such as glass, ceramic tiles, rubber, etc. But before solidification, some of its monomers can easily cause allergic reactions in some people.

Divided by colorants:

1 dye ink

Dye ink is a fully soluble ink at the molecular level, which is a complete composite solution with a low probability of blocking the ink head. After spraying, it is easy to be absorbed by the material, with bright colors and low cost,

The disadvantage is that its waterproofing is weak, and due to the rapid decomposition of dye molecules under ultraviolet radiation, it is suitable for indoor use.

The advantages are bright colors, clear layers, and lower prices compared to pigment based inks, making it the preferred product for printing pictures, making color inkjet business cards, and other related products.

2 pigment ink

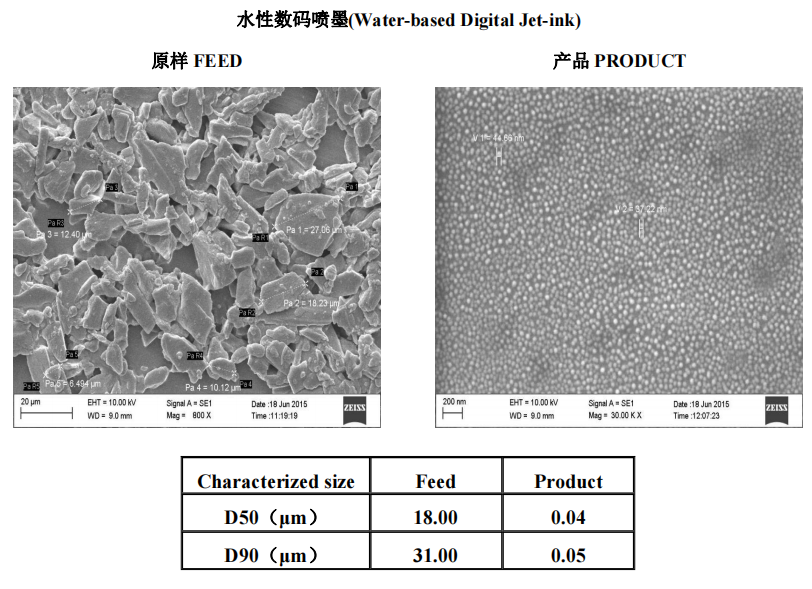

It grinds solid pigments into very small particles and suspends them in a special aqueous solvent. It is a suspension solution or semi solution, which has the same properties as the pigments used for printing and dyeing clothes. The principle of color formation is completely opposite to that of dye ink penetrating into the medium, which is achieved by attaching the color material to the surface of the medium (such as copy paper or printing paper).

Therefore, its advantage is that the pigment itself is waterproof and not easily decomposed by ultraviolet radiation. Strong water resistance and light resistance. Therefore, it is suitable for outdoor use.

The disadvantage is that most pigment inks will leave residual color on the surface, so even printing on flat paper cannot produce a glossy image. In addition, the manufacturing cost of pigment ink is relatively high.

Classification of digital ink types by environmental protection level:

Water-based ink

UV Curable Ink (UV)

Biological ink

Recommended equipment: SP series bead mill without shaft seal and screen