Service hotline

86-18561281819Product details

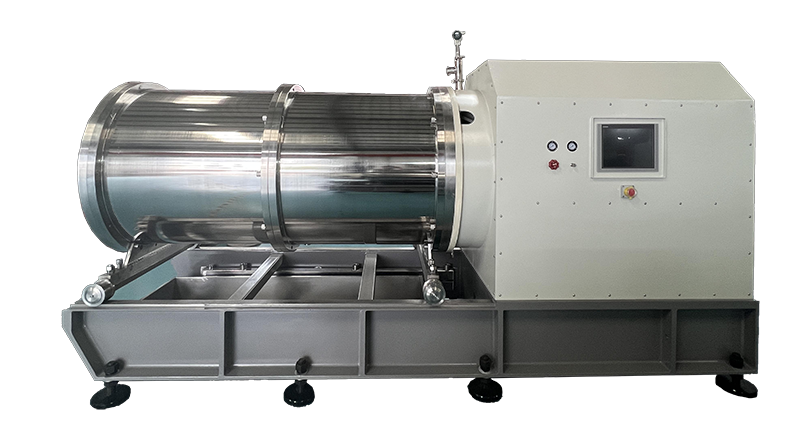

- WX/WS Series Horizontal Bead mill

- Company Name: Weihai Sanxing Feirong Nano Technology Co., Ltd.

- Contact number: 86-18561281819

- Contact address: No.2 Carbon Fiber Industrial Park, East Jiangsu Road, Lingang Development Zone, Weihai, Shandong, 264200, P. R. China

Product Description

The bead mill is a sharp tool for preparing nano materials in large quantities by physical method, and is also considered as one of the grinding equipment with the most extensive particle size, the most advanced progressiveness and the highest grinding efficiency. The production of Lithium iron phosphate must use crushing and classification equipment. Only when Lithium iron phosphate is crushed to enough fineness, and the fine powders with different fineness are graded and efficiently utilized, can the high-quality production of lithium ion batteries be achieved. At present, the large-scale horizontal bead mill on the market has several pain points in grinding LFP (Lithium iron phosphate):

1. Easy to block the screen (at least 3-4 days, at most half a month);

2. Lack of grading grinding function and the grinded powder with wide particle size distribution;

3. High energy consumption and low efficiency;

4. Difficulty in using 0.2mm zirconium beads to grinding powder to 150nm

In response to the above pain points, Sanxing Feirong has developed a new WX series industrial production horizontal bead mill, which has the following characteristics:

1. Dynamic separation screen + multi-stage turbine, completely solving the problem of screen blockage;

2. Circulation flow field design, grading separation and grading grinding function with high efficiency, narrow particle size distribution;

3. Rare earth permanent magnet motors further reduce energy consumption;

4. 0.2mm zirconium beads can be used, with a fineness of up to 150nm.

Equipment characteristics

1.Good size ratio design, high energy density, suitable for high quantity production

2.Dynamic centrifugal bead separation system, without material blockage, bead leakage and screen blockage/span>

3.The minimum grinding medium can be Φ 0.2mm, capable of achieving nano level grinding

4.The viscosity range of the slurry is wide, suitable for 20Mpa to 5000Mpa

5.Combined high-efficiency grinding structure design, low motor power, and low unit energy consumption

6.Adopt internal and external circulation grinding flow field and grading grinding design, with high grinding efficiency and narrow particle size distribution

7.Reasonably match the combined rotor structure according to different fineness requirements: rod pin, turbine, and dispersion disc

8.The grinding tank is made of silicon carbide material, which has good wear resistance, corrosion resistance, good cooling effect, and low discharge product temperature

9.Adopting rare earth permanent magnet motors, the structure is compact and simple, saving more than 15% energy compared to three-phase asynchronous motors

10.The equipment is easy to operate and process control, and installation, operation, and maintenance are convenient

Equipment parameters

|

Model |

Effective volume (L) |

Motor power (KW) |

Ball diameter (MM) |

Beading (VOL%) |

Overall dimensions (MM) |

Weight (KG) |

|

WX/WS-2 |

2 |

7.5/4.5 |

0.2-2.0 |

3月10日 |

880x 700x720 |

120 |

|

WX/WS30 |

30 |

45/37 |

0.2-2.0 |

70-80 |

1830x 1350x1800 |

2200 |

|

WX/WS100 |

100 |

90/55 |

0.2-2.0 |

70-80 |

3130x 1450x2450 |

4600 |

|

WX/WS200 |

200 |

160/90 |

0.2-2.0 |

70-80 |

3550x 1450x2570 |

5200 |

|

WX/WS300 |

300 |

250/132 |

0.2-2.0 |

70-80 |

3570x 1450x2580 |

5600 |

|

WX/WS500 |

500 |

400/250 |

0.2-2.0 |

70-80 |

3700x 1450x2590 |

6500 |

|

WX/WS1000 |

1000 |

650/355 |

0.2-2.0 |

70-80 |

4500x 1650x2850 |

9500 |